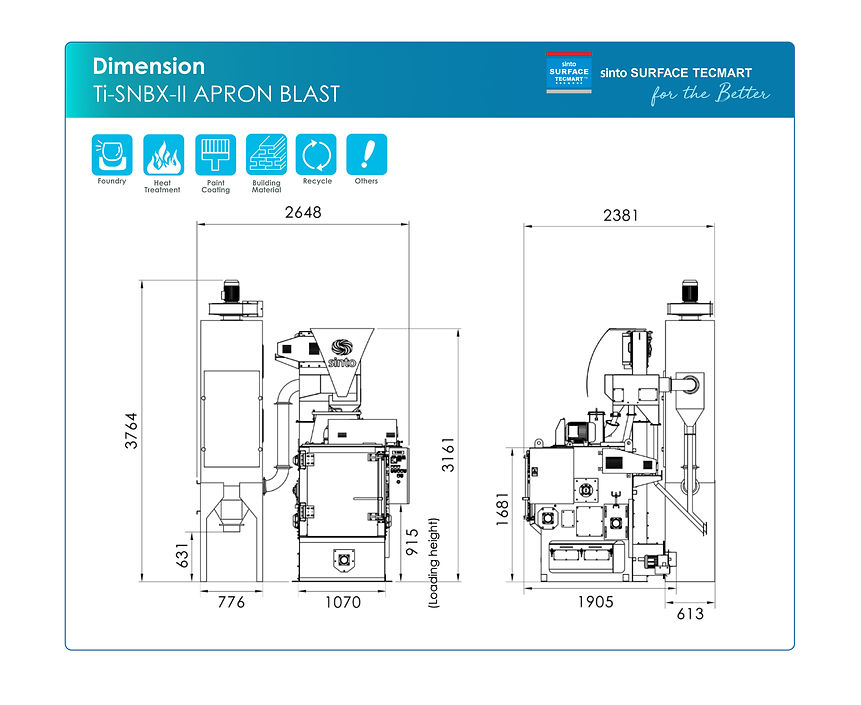

Ti-SNBX-II APRON BLAST

Features

Specifications

features

“Zero*” shot leak

With the new design, Ti-SNBX-II can bring about zero* percent shot leak.

This in return leads to less abrasives consumption expenses as well as creates better and clean working environment

* Remark: Zero% in our definition means shot leaks of less than 1000g/year

Efficient mechanism

Ti-SNBX-II is equipped with impeller that has motor directly attached to it as driven unit and because of this mechanism energy losses are

Easy to install and relocate

Dust collecting unit is attached to shotblasting main unit; therefore, due to its compact size, installation and/or machine relocation can be easily performed.

application

Blasting Cabinet

Peening process that gives new value to materials and supports advanced fields Polishing technology that can achieve rounded edges and deburing of tiny,delicate parts.

We provide surface characteristics that can fulfill the functions our customers require such as smooth surfaces and non-slip surfaces.

We help to discover the surface characteristics that bring out the advantages surfaces of each kind of material.

specifications