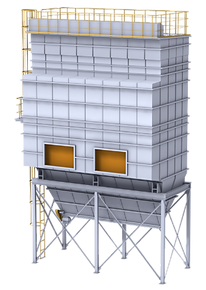

Dust Collector Technology Cleans the Air

The keys to improving workplace environment are in our know-how supported by technologies and experience

and in sealded dust collection planning. Dust and smoke significantly vary in concentration, volume, temperature, composition, etc. depending on the customer's operations and process.These factors and more form a complicated relationship when planning dust collection. Sinto has shown first-in-class domestic achievements in delivering dust collectors and offers environmentally-friendly,easy-to-operate, and safe dust collection systems engineered with our accumulated technologies, experience and know-how.

We Offer Optimal Dust Collection Systems to the Customers

Unique dust collectors applicable to all types of dust and featuring lower space requirements and excellent energy efficiency are available. We recommend a variety of optimal dust collection systems according to the nature of the dust to be generated, processing temperature and gas composition.