SERVICES & MAINTENANCE

One of our keyservice categories is installation work Major foundry plants in Thailand who kindly selected Sintokogio foundry equipment all trusted us in providing this service. In most cases we deliver Our service as turnkey so that our customers do not have to worry about a single thing Qualified local Thai engineers and foremen are supervised by our Japanese supervisors Big projects like this usually require good equipment and software synchronization in order to complete an installation which only Thai Sinto can offer.

Other key important type of businesses that we provide to our customer is after-sales maintenance support.We usually recommend our customer to conduct preventive maintenance in order to minimize downtime as much as possible and we will dispatch our well-trained engineering staff to guide the customer along the way. Nonetheless, when accident arises once the machine actually breaks down, we will send our team to inspect at site and conduct repairing to revive the machine. Our maintenance team with qualified skills and extensive experience will standby for you 7 days week without holiday even during the New Year.

SINTO SMART FOUNDRY Good Casting System

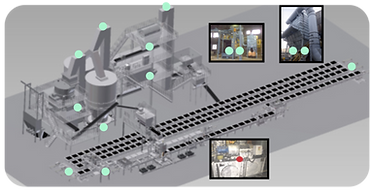

Remote Monitoring System

Production Monitor from Anywhere

Child Sensors

Gateway

Mother Receiver

Monitor your facility with Sinto’s completely wireless vibration and ambient temperature sensors. The Sinto Smart Foundry® Toolbox offers Remote Sensors to help monitor your facility through its completely wireless vibration and ambient temperature sensor. The data can be viewed on any device with a web browser.

-

Users' friendly interface

-

Tablet & smart phone web application

-

On-line technical services

-

Applied to all machines

FEATURES

-

Real-time data down-time reduction

-

Just-in-time spare parts purchase

-

Employees' safety

ADVANTAGES

SERVER data

collection Notification

Best locations to install sensors are hazardous locations or places that cannot be easily accessed such as Dark place, High place, Narrow place, Moving part.

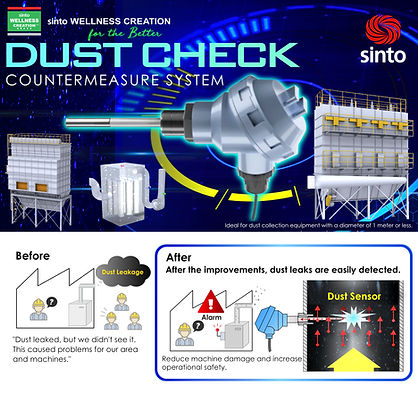

DUST CHECK COUNTERMEASURE SYSTEM

These sensors identify dust leaks caused by burned or torn filters and put out a signal for abnormalities, for effective detection of fires during dust collector operations.

Immediately detect fires during dust collector operations

Early fire detection system

Dust leak sensors

These sensors identify dust leaks caused by burned or torn filters and put out a signal for abnormalities, for effective detection of fires during dust collector operations.

Smoke sensors

These sensors identify smoke from fires and put out a signal for abnormalities, for effective detection of fires when dust collectors are not in motion.

Temperature sensors

These sensors detect temperature increases inside the dust collector due to fire and put out a signal for abnormalities.

Dust Accumulation Detection Device

Features of Our Detection App

-

Color Shade Change within Temperature Range: The app can change its color shade within a specific temperature range on the color bar.

-

Adjustable Sensitivity: You can adjust the sensitivity of the detection.

-

Configurable Categories: Each type or category of detection can be individually configured.

-

View Photos and Videos: You can review captured photos and videos.

-

Photo Capture: The app can take photos.

-

Video Recording: The app can record videos.

-

Switch Detection Modes: You can change between different detection modes.

-

Freely Adjustable Temperature Range: The upper and lower values of the temperature range can be adjusted independently.

Automatic Mode

When the device's center is pointed at the pipe, it will automatically calculate and display the appropriate colors for detection.

Examples

Visual Photography

Infrared imaging

Dust Accumulation Detection Device vs. General Infrared Camera Usage

User-friendly for in-pipe dust inspection.

The device is portable and easy to use.

The outline view uses color to clearly differentiate temperatures.

Clear images with a high-resolution camera.

It can detect even when surrounded by objects with low or high temperatures.

Manual Mode

Users can freely set the color-changing temperature distribution values.

Avg. 29.6°C Max. 46.9°C Min. 23.8°C

Dust Accumulation Detection Device

Features of Our Detection App

-

Color Shade Change within Temperature Range: The app can change its color shade within a specific temperature range on the color bar.

-

Adjustable Sensitivity: You can adjust the sensitivity of the detection.

-

Configurable Categories: Each type or category of detection can be individually configured.

-

View Photos and Videos: You can review captured photos and videos.

-

Photo Capture: The app can take photos.

-

Video Recording: The app can record videos.

-

Switch Detection Modes: You can change between different detection modes.

-

Freely Adjustable Temperature Range: The upper and lower values of the temperature range can be adjusted independently.

User-friendly for in-pipe dust inspection.

The device is portable and easy to use.

The outline view uses color to clearly differentiate temperatures.

Clear images with a high-resolution camera.

Examples

Visual Photography

Infrared imaging

It can detect even when surrounded by objects with low or high temperatures.

Automatic Mode

When the device's center is pointed at the pipe, it will automatically calculate and display the appropriate colors for detection.

Manual Mode

Users can freely set the color-changing temperature distribution values.

Avg. 29.6°C Max. 46.9°C Min. 23.8°C

SINTO Siambrator Service Center

Testing

-

Abrasive Quality

-

Blasting Condition

-

Profile roughness

-

Other upon require

Training

Getting to know more on the Abrasive, Shot Blasting machine and the Blasting process, review the important points to focus especially, the safety at your work. Please contact us for more detail

From the experience as a manufacturer and being a leader in the market for over 30 years, Siambrator Co., Ltd. realizes how importance of quality and service are. To meet the needs of customers and provide comprehensive services, we has set up a Service Center to be a center that can support knowledge and training, testing, as well as consulting to enable customers to work and reduce costs in the blasting process effectively.

Technical and consulting support